3D printing has come a long way from hobbyist projects on the kitchen table to professional-grade manufacturing. As printers become more powerful, many users wonder: Do I really need a 3D printer enclosure? While it might seem optional, an enclosure can make a surprising difference in print quality, safety, and overall consistency.

In this article, we’ll break down what an enclosure actually does, when it’s necessary, and what benefits (and drawbacks) it brings to your setup.

What Is a 3D Printer Enclosure?

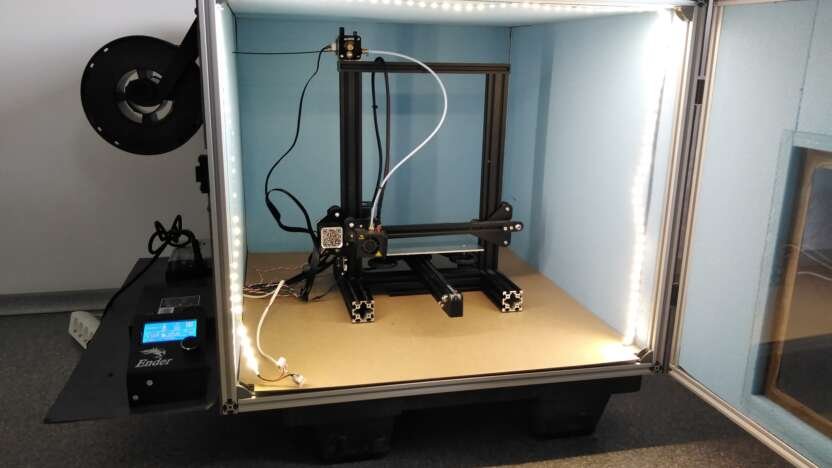

A 3D printer enclosure is a dedicated chamber or box that surrounds your printer to create a controlled environment. It helps maintain a steady temperature, reduces exposure to drafts, and minimizes noise.

Beyond temperature regulation, it also provides an added layer of protection keeping curious pets, children, or debris away from your printer during operation. Whether it’s made of acrylic panels, aluminum frames, or DIY plexiglass kits, an enclosure adds both function and safety to your 3D printing setup.

Why Temperature Control Matters

Temperature consistency is one of the biggest challenges in 3D printing. When the surrounding air cools too quickly, materials like ABS, PETG, or Nylon can warp, crack, or peel away from the print bed.

A printer enclosure helps by trapping heat inside, preventing these temperature swings. This steady environment ensures that each layer bonds smoothly with the previous one, leading to stronger, cleaner prints.

Benefits of Temperature Stability:

- Reduced warping: Prevents cooling inconsistencies on large prints.

- Better adhesion: Layers fuse more tightly for greater durability.

- Improved precision: Keeps your nozzle and filament performing consistently.

Safety and Air Quality

Safety is another major reason to consider an enclosure. When printing with materials like ABS or ASA, your printer can release small amounts of fumes or ultrafine particles.

An enclosed 3D printer setup can limit exposure by containing these emissions. Many enclosures also allow the addition of HEPA or carbon filters that remove odors and particles before they reach your workspace.

Additionally, it acts as a protective shield keeping hot components and moving parts safely out of reach.

Noise Reduction and Workspace Comfort

If you’ve ever left your printer running overnight, you know how noisy it can get. The hum of stepper motors, fans, and belts can quickly become a distraction.

An enclosure for your 3D printer can significantly reduce that noise. The walls act as sound barriers, absorbing and dampening vibrations, which makes your workspace quieter and more comfortable especially in home or office settings.

When You Might Not Need an Enclosure

Not every printer setup needs an enclosure. For example, if you primarily print with PLA (a low-temperature filament that doesn’t warp easily), you might not benefit much from one.

PLA performs well in open-air environments, and enclosing it could even make cooling less efficient. Likewise, if you’re running short prints or small prototypes in a well-ventilated area, the difference might be minimal.

However, if you use materials that require controlled conditions or you’re working in a room with temperature fluctuations the benefits become clear very quickly.

Types of 3D Printer Enclosures

There are many ways to add an enclosure to your setup, depending on your needs and budget:

1. Pre-Built Enclosures

Manufacturers like Prusa, Creality, and Flashforge offer official or compatible enclosures designed for their models. These are ready to use, easy to assemble, and often include temperature and airflow control features.

2. DIY Enclosures

Many makers build their own using plexiglass panels, IKEA cabinets, or aluminum frames. DIY setups are cost-effective and customizable, letting you add features like lighting, ventilation, or insulation.

3. Custom Modular Systems

Some high-end users opt for modular or expandable designs that integrate with large-format printers. These are ideal for professionals printing at scale or experimenting with high-performance materials.

Drawbacks to Consider

While enclosures offer many advantages, they’re not perfect.

Here are a few potential downsides:

- Cost: Pre-made enclosures can add a few hundred dollars to your setup.

- Accessibility: Some designs make it harder to reach the printer during operation.

- Heat buildup: Without proper ventilation, excessive heat can affect prints or electronics.

However, most of these issues can be addressed with proper setup and maintenance such as adding temperature monitors or small exhaust fans.

Choosing the Right Enclosure

When selecting or building your enclosure, consider the following:

- Material compatibility: Make sure it fits your printer’s size and material needs.

- Ventilation: Add filters or fans if printing with ABS or other fume-producing materials.

- Visibility: Transparent panels help you monitor prints without opening the chamber.

- Accessibility: Include removable panels or hinged doors for easy maintenance.

A well-designed enclosure not only improves performance but also makes your setup look cleaner and more professional.

Final Thoughts

So, do you really need a 3D printer enclosure?

If you print with temperature-sensitive materials or care about consistent, professional-quality results the answer is yes.

An enclosure stabilizes your environment, reduces noise, and keeps you safe from fumes or burns. Whether you buy a pre-built model or build a 3D printing cabinet yourself, it’s one of the smartest upgrades you can make to your workspace.

Your prints will be smoother, stronger, and more reliable and your 3D printing experience will feel far more refined.